| Filling Method |

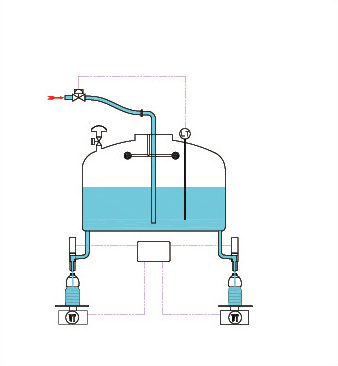

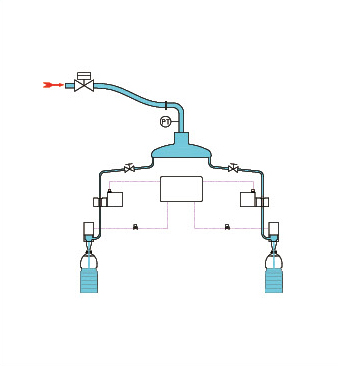

Mechanical Valve Filling |

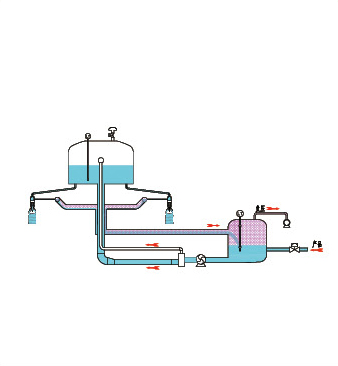

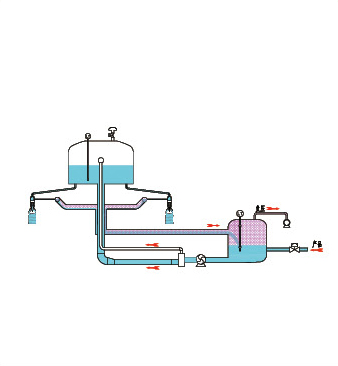

Flow Meter Filling |

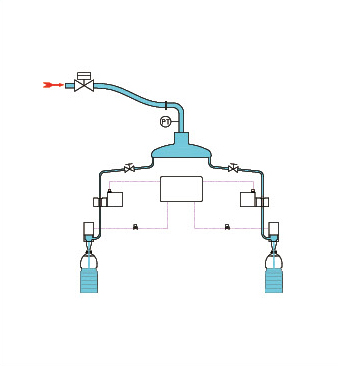

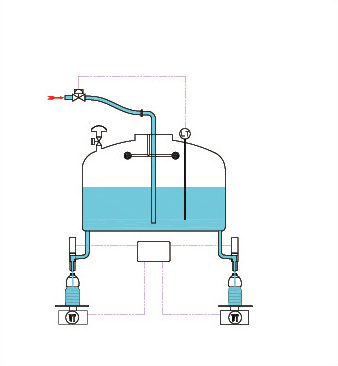

Weigh Filling |

| |

|

|

|

| Applicable Bottle Type |

PET/Glass/HDPE/PE/Aluminum Bottle |

PET/Glass/HDPE/PE/Aluminum Bottle |

PET/Glass/HDPE/PE/Aluminum Bottle |

| Technical Features |

Different length of air vent tubes to control fill level Hygienic design Filling with reflux or filling without reflux To guarantee the fill level with vacuuming device |

Accurate fill level control Maintenance free flow meters Automatic CIP dummy bottle Optimal flow path in filling valves to ensure the complete CIP Selection of flow meters based on the product conductivity Faster filling speed Fast recipe change Easy maintenance |

Weighing instrument to control filling accuracy, free of filling volume limits Reliable, easy maintenance, regularly adjust for platform Fast recipe change Positive pressure or gravity filling Automatic or manual CIP dummy bottle |

| How to choose |

Fuid features of products Low capex and low operating cost Large container size and filing level as its measuring standard |

Volume as a measuring standard Extremely high requirement for filling accuracy Different bottle sizes in one machine More rigorous hygienic requirements |

Weight as a measuring standard Extremely high requirement for filling accuracy Different bottle sizes in one machine More rigorous hygienic requirements Large size containers filling |

| Capacity |

36000bottles per hour |

36000bottles per hour |

36000bottles per hour |