|

HPC products, such as laundry detergent, dish washing detergent, shampoo, thimerosal, hair conditioner, fabric softener, mouthwash, have irregular shapes in container and cap. Their packaging container keeps changing. During filing, foaming, stringing, dripping etc. are all the difficult points. The filling accuracy and hygienic requirements are also rigorous. Capacity requirement is also becoming a new tendency for filling equipment. All these factors launched a challenge for filling technology. Tech-Long HPC filling machines fully consider all the key points. With our core technology and rich experience, we will provide you with a filling solution for your requirement. It will simplify your operations. | |

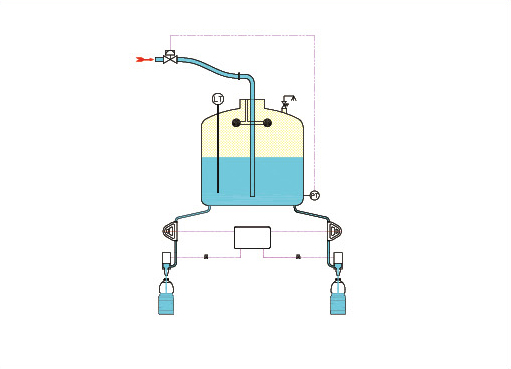

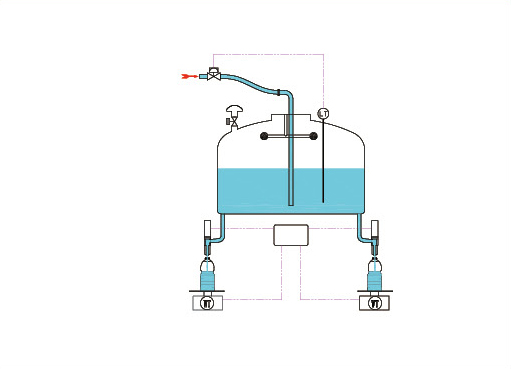

| Filling Method | Flow Meter Filling | Weigh Filling |

|

|

|

| Applicable Bottle Type | PET/Glass/HDPE/PE Bottle | PET/Glass/HDPE/PE Bottle |

| Technical Features | Accurate fill level control Maintenance free flow meters Automatic CIP dummy bottle Optimal flow path in filling valves to ensure the complete CIP Selection of flow meters based on product conductivity Faster filling speed Fast recipe change Easy maintenance | Weighing instrument to control filling accuracy, free of filling volume limits Reliable, easy maintenance, regularly adjust for platform Fast recipe change Positive pressure or gravity filling Automatic or manual CIP dummy bottle |

| How to choose | Volume as the measuring standard Filling products are even Frequent bottle change | Weight as the measuring standard Filling products are even or not even Large container size |

| Capacity | 36000 bottles per hour | 36000 bottles per hour |