| Filling Method |

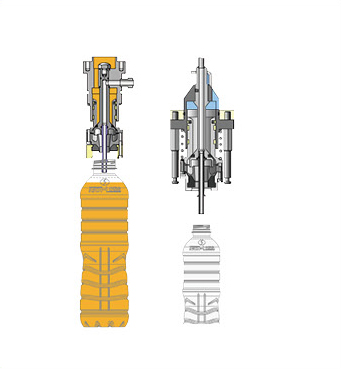

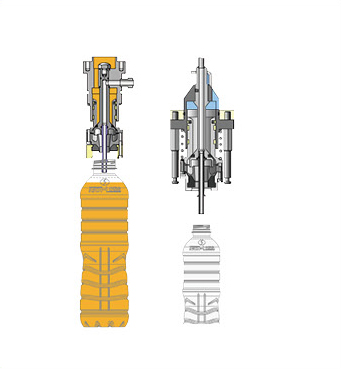

Mechanical Valve Filling |

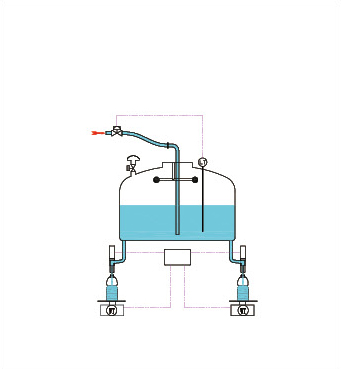

Flow Meter Filling |

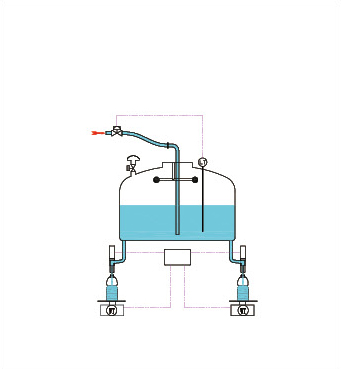

Weigh Filling |

| |

|

|

|

| Applicable Bottle Type |

PET/Glass/Aluminum Bottle |

PET/Glass/Aluminum Bottle |

PET/Glass/Aluminum Bottle |

| Technical Features |

Different length of vent tubes to control fill level Hygienic design Filling with reflux or without reflux To guarantee the fill level with vacuum device |

Accurate fill level control Non-contact filling Automatic CIP dummy bottle Optimal flow path in filling valves to ensure the complete CIP Adaptable to light weight bottle Fast recipe change Easy maintenance |

Online weighing instrument to conrol the accuracy of filling level Non-contact filling design, safe and hygienic Optimized liquid piping design Fast filling speed Pre-reserved different filling recipes, easy to change |

| How to Choose? |

Low capex and low operating cost |

More hygienic filling Accurate filling Automatic CIP dummy bottle |

Weight as the measuring standard Higher requirements for filling accuracy Different size of bottles in one machine More hygienic requirement Large size container filling |

| Capacity |

60,000 bottles per hour |

60,000 bottles per hour |

24,000 bottles per hour |